hydraulic transmission-manufacture,factory,supplier from China

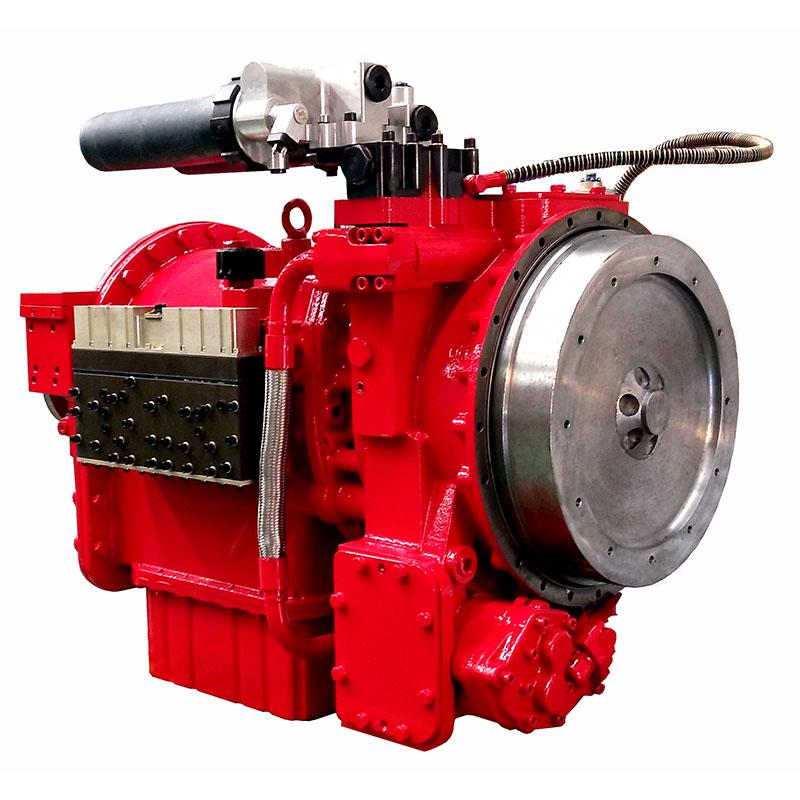

This product is a new product with completely independent intellectual property rights developed by Jichai on the basis of 20 years of technical accumulation, historical background, and integration of advantageous resources in the industry. The products are integrated with a single-stage two-phase hydraulic torque converter, one-way clutch, locking clutch, hydraulic retarder, planetary transmission, power shift, ECU control, electro-hydraulic shift valve set, and other system units, which have the advantages of compact structure, easy operation, and reliable operation.

| technical parameter | Rated output power | 410kW |

| Rated input speed | 2100r/min | |

| Input interface | SAE NO.1 | |

| Force reclaimer interface | two,Top PTO、Side PTO | |

| Hydraulic retarder/distributor box | selected |

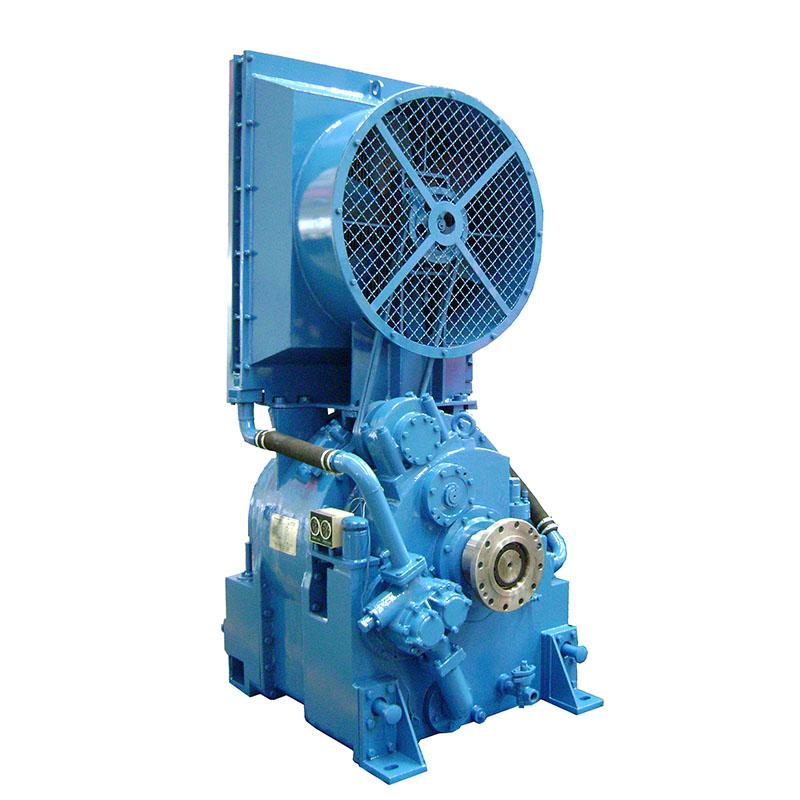

The hydraulic torque converter is a flexible transmission device installed between the power machine (such as diesel engine and electric motor) and the working machine (such as a winch, rotary table, and drilling pump), using mineral oil as the working medium and transmitting power of the power machine to the working machine.YBLT900 hydraulic torque converter is a centrifugal turbine torque converter with a charging and adjusting valve and its working chamber diameter is 900mm.It is compatible with G12V190PZL (or CAT3512) diesel engines and is mainly used on oil rigs.

| Technical specification | Maximum input speed | 1500 r/min |

| Maximum input power | 810kW | |

| Maximum input moment | 6.5k Nm | |

| Maximum output moment | 38.0 km | |

| Peak efficiency | 85±2% | |

| Cavity diameter | 900 mm | |

| Fuel supply pressure | 0.3~0.47 MPa | |

| Operating oil temperature | ≤110℃ | |

| Net quality | 2100kg | |

| Overall dimension (length × width × height) | 1330×950×1073 mm |

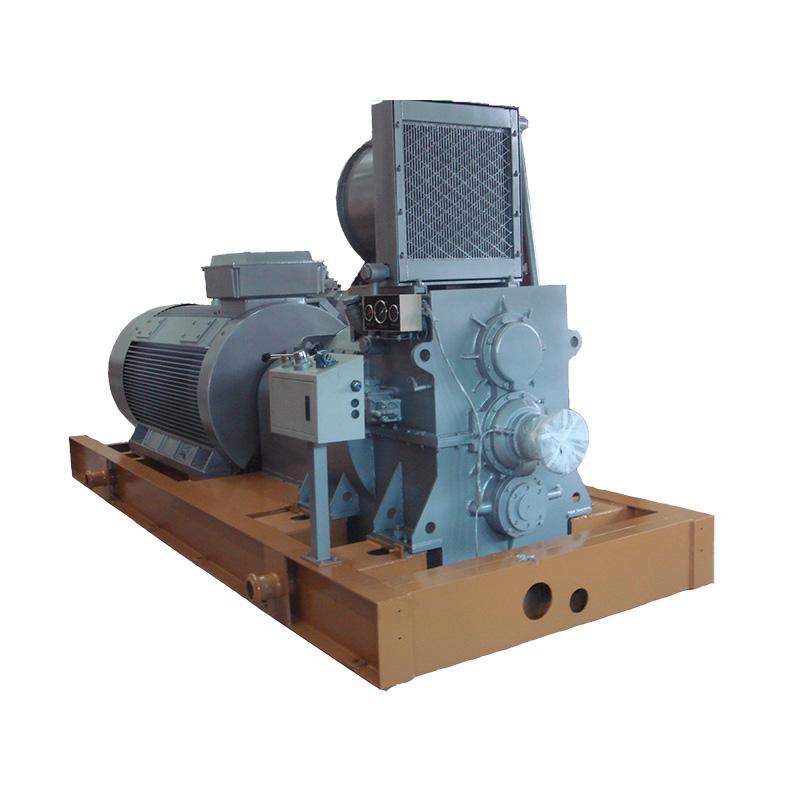

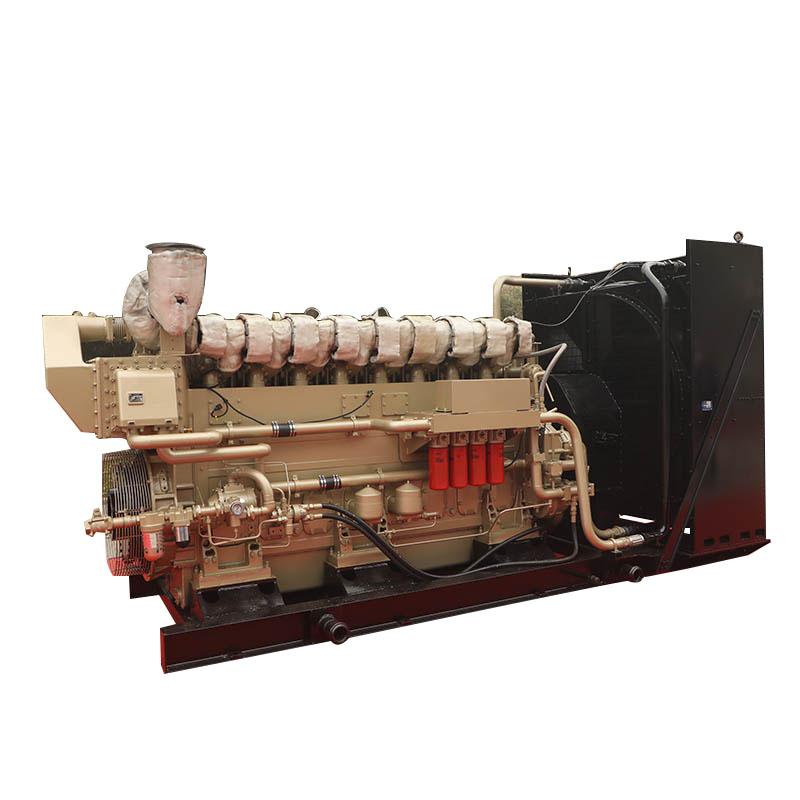

This power unit is used to replace the single pump unit of diesel engine mud pump with traditional configuration, and the mechanical reducer, airbag clutch, and transmission belt with traditional configuration are cancelled. It has a compact structure and easy operation and maintenance. Power range of the unit: 105kW(140Hp) ~ 3000kW(4000Hp), fully meeting the driving requirements of the existing drilling rig with a 200-2200hp mud pump.

| Technical parameter | Input speed | 600~1500 r/min | |

| Power range | 300~2000 kW | ||

| Rated slip | 3% | ||

| Rated efficiency | ≥96% | ||

| Reduction ratio | 2.0~3.3 | ||

| Speed adjustable range | 1/3 | ||

| Clutch sensitivity | 6~8S | ||

| Gear reduction ratio | 2.0~3.3 | ||

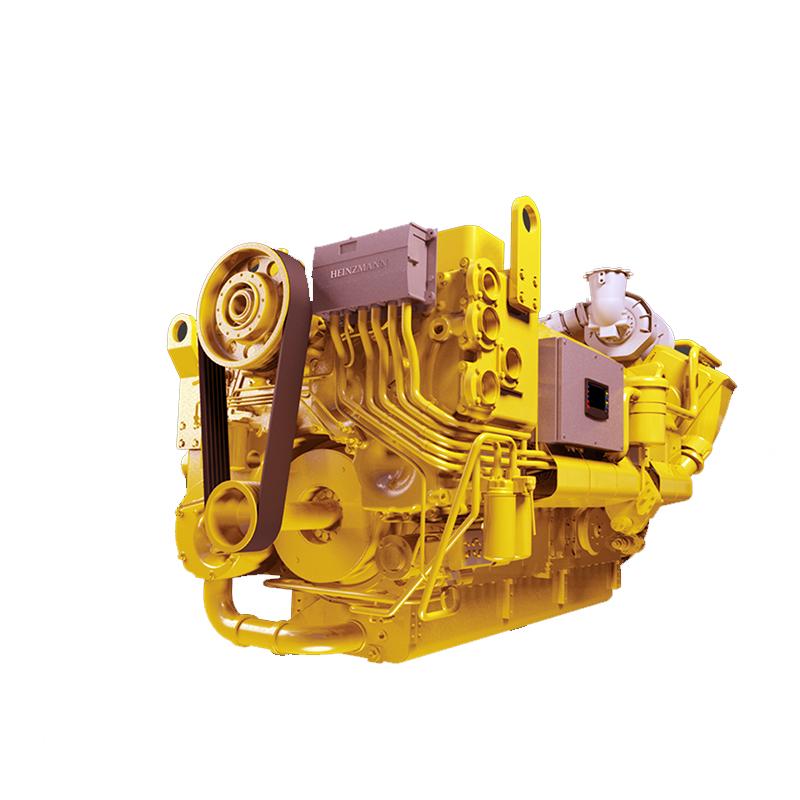

12V175 diesel engine with high pressure, low energy consumption, high reliability, long life characteristics, Through the use of electronic control, high-pressure common rail, Miller cycle, exhaust post-treatment, high-efficiency supercharger, and other new technologies, the engine power performance, economy, reliability, emission index, and other aspects reach the international advanced level: the average effective pressure of diesel engine reaches 2.0MPa, the first overhaul period reaches 35,000 hours, the bare-machine emissions meet GB20891 II.

| Description | Engine model | Injection system | Speed adjustment mode | Cylinders & Arrangement | Cylinders Bore,mm | Piston Stroke,mm |

| Engine with fan and radiator | 12V175PZL-1/0 | ECU electric monoblock pump | Electronic Speed Governor | 12 cylinders, V type | 175 | 190 |

| Description | Gensets Model | Rated power kw | Rotation speed r/min | Engine model | Hydraulic transmission coupler/Torque Converter Model | Height of center |

| Hydraulic transmission coupling set | 12V175PZL-1/0 | 1097 | 1200 | 12V175PZL-1 | YOZJ750 | 930 |

The electric motor coupling power unit is driven by electric motors and makes full use of power grid resources, which realizes the electric driving transformation of traditional mechanical drilling machine, reduces drilling cost, improves economic benefits, effectively reduces drilling noise, and has no exhaust emission, thus greatly improving the working environment. The unit is powered by a high-power electric motor, and users can make full use of cheap grid power resources to reduce the drilling cost by 30% ~ 45%. It is especially suitable for areas with long drilling cycles, complicated geological conditions, inconvenient transportation and concentrated well locations.

| Technical parameter | Input RPM | 600~1500 r/min | |

| Power ange | 300~1200 kW | ||

| Rated slip | 3% | ||

| Rated efficiency | ≥96% | ||

| Reduction ratio | 1.1~3.3 | ||

| Speed range | 1/3 | ||

Series 4000 long-stroke diesel engine is designed and developed according to the current domestic and foreign internal combustion engine industry development situation, combining with Austria AVL simulation analysis software from Liszt, and combining with its own years of product research and development experience and cooperation with domestic universities and research institutions.

The dynamic performance, economic performance, reliable performance, and other indicators of the product have reached the international level, with the characteristics of compact shape, simple operation, and maintenance, high power index, it can match 50Hz and 60Hz frequency operated motor and meet various power needs.

| Description | Engine model | Injection system | Speed adjustment mode | Cylinder&Arrangement | Cylinders bore,mm | Piston stroke,mm |

| Engine with fan and radiator | BL12V190PZL-1 | Monoblock Pump | Hydraulic or Electro-hydraulic Governor | 12 cylinders,V type | 190 | 255 |

| BL12V190PZL-2 | ||||||

| BL12V190PZL-3 | ||||||

| AL8190PZLG-1 | ECU Electric Control Monoblock Pump | Electronic speed governor | 8 cylinders L type | |||

| AL8190PZLG-3 | ||||||

| Description | Genset model | Rated power kw | Ratation speed r/min | Engine model | Hydraulic transmission coupler/Torque Converter Model | Height of center |

| Hydraulic transmission coupling set | BL12V190PZL-3/O | 1300 | 1300 | BL12V190PZL-3 | YOZJ875 | 760 |

| CO1300-3/20 |

Series 6000 land-used diesel engine is developed by Jichai with Austria AVL company and domestic well-known colleges and universities, research institutes, and by means of the latest development of internal combustion engine, through the computer-aided design, simulation, finite element analysis and research on the combustion process, the crankshaft torsional vibration of engine and turbocharger matching, into the exhaust system on the basis of the simulation, optimization of design and development. The advanced technology and mature parts and components of the current international high-power internal combustion engine industry are adopted, so that the engine can not only expand the power of the original 190 series diesel engine, but also make great progress in improving the average effective pressure, reducing fuel consumption and emission, and improving the reliability and safety of use.

| Description | Engine model | Injection system | Speed adjustment mode | Cylinder&Arrangement | Cylinders Bore,mm | Piston Stroke,mm |

| Engine with fan and radiator | H12V190PZL | Monoblock pump | Electronic Speed Governor | 12 cylinders,V tyoe | 190 | 215 |

| H12V190PZL-1 | ||||||

| H12V190PZL-2 | ||||||

| Description | Genset model | Rated power kw | Rotation speed r/min | Engine model | Hydraulic transmission coupler/Torque Converter Model | Height of center |

| Hydraulic transmission coupling set | CO2200/40 | 2200 | 1500 | H16V190PZL | YOTFJ875 | 760 |

Hydraulic Coupler widely used in the field of oil drilling and has become the standard configuration of the diesel coupling power units for oil drilling rigs.

| Technical parameter | Input speed | 600~1500 r/min | |

| Transfer power range | 600~1300 kW | ||

| Rated slip | 3% | ||

| Rated power | ≥96% | ||

| Reduction ratio | 1.1~3.3(According to user form a complete set of circumstances specific determination) | ||

| Characteristic | Independent air cooling | This type of hydraulic coupler adopts the same water-cooling system as the diesel engine, which is installed on the common chassis, easy to install and transport, safe and reliable to operate. | |

| Combined water cooling | This type of hydraulic coupler adopts an independent fan cooling system for the ahead gearbox, which is suitable for the selection of all types of drilling rigs. | ||

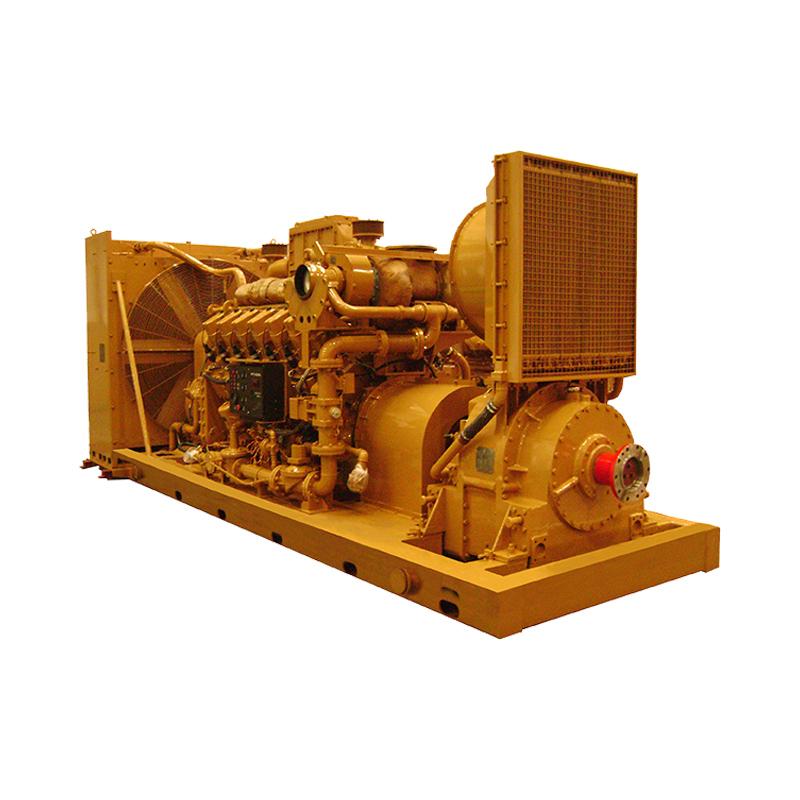

so as to better meet the power requirements of various oil drilling rigs, generator sets and construction machinery.2000 series diesel engine can be matched with torque converter engine set, Hydraulic transmission coupling set and diesel generator set, used for driving drilling rigs or mud pumps, and can also be matched with fire pump, flood pump, etc.

| Description | Engine model | Injection system | Speed adjustment mode | Cylinders & Arrangement | Cylinders bore,mm | Piston Stroke,mm |

| Engine with fan and radiator | G12V190PZL | Monolithic plunger type sundstrand pump | Mechanical speed control or electrical control | 12 cylinders ,V type | 190 | 210 |

| G12V190PZL-1 | ||||||

| G12V190PZL-2 | ||||||

| G12V190PZL-3 | ||||||

| AG12V190PZL | ECU electric control jet sundstrand pump | Electronic speed governor | ||||

| AG12V190PZL-3 | ||||||

| Description | Genset model | Rated power kw | Ratation speed r/min | Engine model | Hydraulic transmission coupler | Height of center |

| Hydraulic transmission coupling set | G12V190PZL-1/O | 740 | 1200 | G12V190PZL-1 | YOZJ750 | 760 |

| CO740F-1/22 | ||||||

| G12V190PZL-3/O | 810 | 1300 | G12V190PZL-3 | |||

| CO810-3/20 | ||||||

| G12V190PZL-O | 900 | 1500 | G12V190PZL | |||

| CO900F/33 | ||||||

| Torque converter set | G12V190PZL-1/B | 620 | 1200 | G12V190PZL-1 | YBX900 | 760 |

| G12V190PZL-3/B | 680 | 1300 | G12V190PZL-3 | |||

| G12V190PZL/B | 760 | 1500 | G12V190PZL |

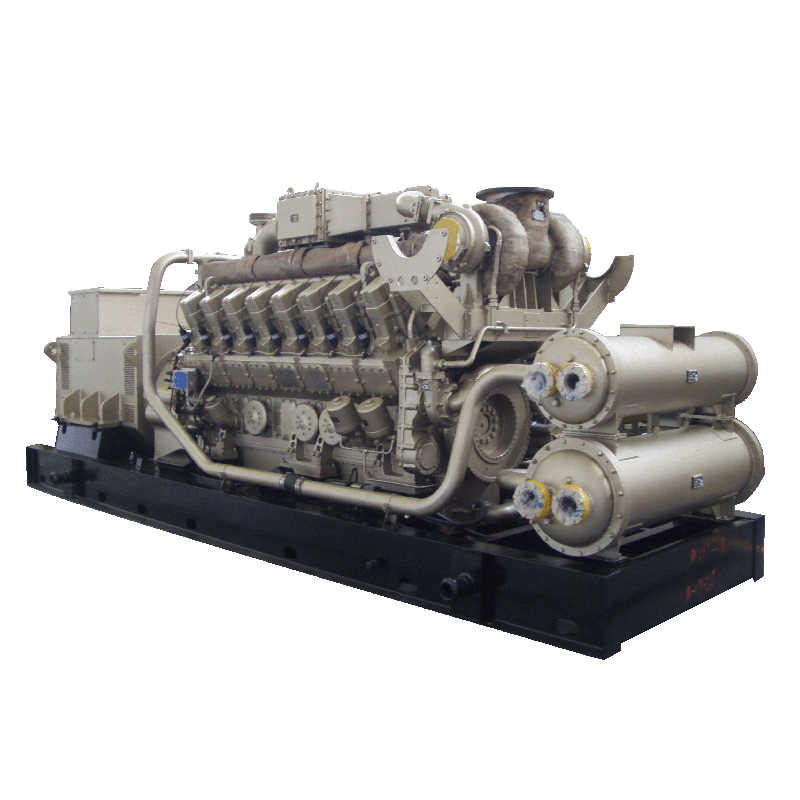

This type of diesel engine is developed on the basis of 6000 series diesel engines, absorbing and learning from the advanced structure and technology of foreign diesel engines. Its dynamic and economic indexes have been greatly improved, and its main performance indexes have reached or approached the international advanced level. Series 3000 diesel engines can meet the demand for power of mechanical drilling machines and electric drilling machines of 4000 to 7000 meters. Can be installed in the same chassis with the torque converter, hydraulics transmission coupling set, used to drive drilling rigs or mud pumps. It can also be used to match the power station composed of single and double supporting generators and the power of a fire pump and flood pump.

| Description | Engine model | Injection system | Speed adjustment mode | Cylinders & Arrangement | Cylinders bore,mm | Piston stroke,mm |

| Engine with fan and radiator | A12V190PZL | Monoblock Pump | Hydraulic or Electro-hydraulic Governor | 12 cylinders ,V type | 190 | 215 |

| A12V190PZL-1 | ||||||

| A12V190PZL-2 | ||||||

| A12V190PZL-3 | ||||||

| B12V190PZL | ||||||

| B12V190PZL-1 | ||||||

| B12V190PZL-2 | ||||||

| B12V190PZL-3 | ||||||

| Description | Genset model | Rated power kw | Ratation speed r/min | Engine model | Hydraulic transmission coupler/Torque Converter Model | Height of center |

| Hydraulic transmission coupling set | A12V190PZL-3/O | 1100 | 1300 | A12V190PZL-3 | YOZJ750 | 760 |

| CO1100-3/15 | ||||||

| A12V190PZL-O | 1200 | 1500 | A12V190PZL | |||

| CO1200/20 | ||||||

| A12V190PZL-1/O | 1000 | 1200 | A12V190PZL-1 | |||

| CO1000F-1/24 | ||||||

| BH12V190PZL-0 | 1360 | 1500 | BH12V190PZL | |||

| CO1360F/33 | ||||||

| BH12V190PZL-3/0 | 1100 | 1300 | BH12V190PZL-3 | |||

| CO1100-3/20 | ||||||

| Torque converter set | A12V190PZL-1/B | 810 | 1200 | A12V190PZL-1 | YBX760 | 930 |

| A12V190PZL-3/B | 880 | 1300 | A12V190PZL-3 | |||

| A12V190PZL/B | 1020 | 1500 | A12V190PZL | YBX720 |

“V” series is the latest design and manufacture lighting tower with the vertical telescopic mast, and the smaller size makes the transportation become more convenient. The “V” series includes VL, VP, VS.

HVP Series Lighting Tower | |||||||

Basic Model | 4HVP4000 | 4HVP1200 | 4HVP1600 | ||||

Dimensions | Length | 4000mm | 4000mm | 4000mm | |||

Width | 1620mm | 1620mm | 1620mm | ||||

Height | 2460mm | 2460mm | 2460mm | ||||

Full extending Heigh | 9m | 9m | 9m | ||||

Genset power(1500/1800rpm-KW) | 6.0/7.5 | 3.0/3.5 | 3.0/3.5 | ||||

Gross weight | 1410kg | 1360kg | 1360kg | ||||

Engine | Engine model | D1105-E2BG-CHN-1 (KUBOTA) | Z482-B-CHN-1 (KUBOTA) | Z482-B-CHN-1 (KUBOTA) | |||

Speed(rpm) | 1500/1800 | 1500/1800 | 1500/1800 | ||||

Number of cylinders | 3 | 2 | 2 | ||||

Engine characters | Vertical, 4-cycle, Water-cooled, diesel engine | Vertical, 4-cycle, Water-cooled, diesel engine | Vertical, 4-cycle, Water-cooled, diesel engine | ||||

Combustion System | E-TVCS | Direct injection | Direct injection | ||||

Engine aspiration | Naturally aspirated | Naturally aspirated | Naturally aspirated | ||||

Emission level | Regular | Regular | Regular | ||||

Alternator | Alternator model | MECCALTE, LT3N-130/4(50HZ), LT3N-100/4(60HZ) | LT3N-75/4 (MECCALTE) | LT3N-75/4 (MECCALTE) | |||

Frequency (HZ) | 50/60 | 50/60 | 50/60 | ||||

Rating voltage (V, AC) | 230V (50HZ), 240V (60HZ) AC | 230V (50HZ), 240V (60HZ) AC | 230V (50HZ), 240V (60HZ) AC | ||||

Alternator insulation | Class H | Class H | Class H | ||||

Alternator protection grade | IP23 | IP23 | IP23 | ||||

Mast & Lights | Type of Lights | Regular metal halide | LED | LED | |||

Light's fixture | Oval | Rectangle | Rectangle | ||||

Luminous flux (LM) | 440000(4×110000)LM | 156000(4×39000)LM | 208000(4×52000)LM | ||||

Number & power of lights | 4×1000W | 4×300W | 4×400W | ||||

Number of mast sections | 7 | 7 | 7 | ||||

Mast extension | Hydraulic | Hydraulic | Hydraulic | ||||

Mast rotation | 359° Manually | 359° Manually | 359° Manually | ||||

Light tilt | Electric | Electric | Electric | ||||

Trailer | Trailer suspension & axle with brakes | Leaf springs & single axle with mechanical brakes | Leaf springs & single axle with mechanical brakes | Leaf springs & single axle with mechanical brakes | |||

Tow bar | Retractable & adjustable supporting wheel tow bar | Retractable & adjustable supporting wheel tow bar | Retractable & adjustable supporting wheel tow bar | ||||

Stabilizing legs & number | 4pcs drawable bar with manual retractable jacks | 4pcs hydraulic pivot legs | 4pcs drawable bar with manual retractable jacks | 4pcs hydraulic pivot legs | 4pcs drawable bar with manual retractable jacks | 4pcs hydraulic pivot legs | |

Wheel's rim size & tires | 16" rim with regular tires | 16" rim with regular tires | 16" rim with regular tires | ||||

Tow adapter | 2" ball coupler or 3" pintle ring | 2" ball coupler or 3" pintle ring | 2" ball coupler or 3" pintle ring | ||||

Tail lights | Tail light kit | Tail light kit | Tail light kit | ||||

Max towing speed | 100km/h | 100km/h | 100km/h | ||||

Additional Features | Fuel tank Type | Double-deck tank | Double-deck tank | Double-deck tank | |||

Fuel tank capacity | 120 liters | 120 liters | 120 liters | ||||

Operating hours with full load | 49/41 hours | 93/84 hours | 93/84 hours | ||||

lighting hours with full fue | 80/69 hours | 200/188 hours | 170/158 hours | ||||

Wires & electric components | Regular | Regular | Regular | ||||

Generator starting type or controller | HGM1790N(SMARTGEN) | HGM1790N(SMARTGEN) | HGM1790N(SMARTGEN) | ||||

Power outlet sockets | 1 unit Euro standard 16A single phase socket | 1 unit Euro standard 16A single phase socket | 1 unit Euro standard 16A single phase socket | ||||

Tool box with the maintenance tools | 1 | 1 | 1 | ||||

Max. against wind when fully extended | 20 m/s | 20 m/s | 20 m/s | ||||

Acoustic pressure | 72dB(A) at 7 meters away | 70dB(A) at 7 meters away | 70dB(A) at 7 meters away | ||||

Standard colour | Any colour for canopy with Black chassis, | Any colour for canopy with Black chassis, | Any colour for canopy with Black chassis, | ||||

Max. # of units loading in 40' high container (Some components would be detached) | 7 | 7 | 7 | ||||

Series 6000 diesel engines are developed by Jichai with Austria AVL company and domestic well-known colleges and universities, research institutes, and by means of the latest development of internal combustion engine, with today's international big power internal combustion engine industry advanced technology and mature component products, make great progress in improving average effective pressure, reducing fuel consumption and improving reliability and safety while expanding the power of the original 190 series diesel engine. Widely used in oil drilling, Marine power, offshore drilling platform, power generation and other fields.

| Genset model | Engine model | Alternator model | Power kW | RPM,r/min | Voltage V | Frequency Hz | Power factor | Dimension mm | Weight kg |

| 1500GF | H12V190ZL | JFG series | 1500 | 1500 | 400 | 50 | 0.8 | 7880×2869×3175 | 19100 |

| 2000GFZ6 | H16V190ZL | 1500 | 1500 | 10500 | 19500 | ||||

| 2000GFZ9 | H16V190ZL | 1500 | 1500 | 5930×2180×2421 | 17000 | ||||

| 1500GF2 | H16V190ZL-1 | IFC series | 1500 | 1200 | 480/13800 | 60 | 7880×2869×3175 | 19500 | |

| 1400GF | H16V190ZL-2 | 2000 | 1000 | 400/6300/10500 | 50 | 9060×2869×3175 | 24000 |

Series 3000 land-used diesel engine is a new generation diesel engine developed by Jichai to meet the demand of the developing petroleum industry and improve the advancement and reliability of our country's drilling equipment. This diesel engine is developed on the basis of 6000 series diesel engines, absorbing foreign advanced structure and technology, and its dynamic and economic indexes have been greatly improved, and its main performance indexes have reached or approached the international advanced level. Series 3000 land-used diesel engines can meet the demand for power of mechanical drilling rigs and electric drilling rigs of 4000 to 7000 meters. Can be installed in the same chassis with the torque converter, coupling set, used to drive drilling rigs or mud pumps. It can also be used to match the power station composed of single and double supporting generators and the power of a fire pump and flood pump.

| Engine model | Fuel injection system | Cylinders & Arrangement | Cylinder bore,mm | Piston stroke,mm | Power factor,kW | RPM,r/min | Total piston displacement,L | Fuel Consumption Rate,g/kW.h | Lub. oil comsumption,g/kW.h |

| A12V190ZL | Four-stroke, pressurized intercooler, water-cooled, direct-injection combustor | 12 cylinders V type | 190 | 215 | 1200 | 1080 | 73.15 | ≤205 | ≤1.0 |

| A12V190ZL-1 | 12 cylinders V type | 1000 | 900 | 73.15 | ≤205 | ≤1.0 | |||

| A12V190ZL-2 | 12 cylinders V type | 900 | 810 | 73.15 | ≤205 | ≤1.0 | |||

| A12V190ZL-3 | 12 cylinders V type | 1100 | 990 | 73.15 | ≤205 | ≤1.0 | |||

| B12V190ZL | 12 cylinders V type | 1320 | 1200 | 73.15 | ≤202 | ≤1.0 | |||

| B12V190ZL-1 | 12 cylinders V type | 1160 | 1060 | 73.15 | ≤202 | ≤1.0 | |||

| B12V190ZL-2 | 12 cylinders V type | 960 | 870 | 73.15 | ≤202 | ≤1.0 | |||

| B12V190ZL-3 | 12 cylinders V type | 1210 | 1100 | 73.15 | ≤202 | ≤1.0 | |||

| BH12V190ZL | 12 cylinders V type | 1360 | 1235 | 73.15 | ≤202 | ≤1.0 | |||

| Genset Model | Engine model | Alternator model | Power kW | RPM,r/min | Voltage V | Frequency Hz | Power Factor | Genset Dimension mm | Weight kg |

| 800GF5 | A12V190ZL-2 | IFC series | 800 | 1000 | 400/6300/10500 | 50 | 0.8 | 6410×2252×2739 | 17200 |

| 1000GF2 | A12V190ZLD1 | 1000 | 1500 | 6250×2250×2739 | 19300 | ||||

| 1100GFZ | A12V190ZLD3 | 1100 | 1500 | 19300 | |||||

| 1200GF | BH12V190ZLD | 1200 | 1500 | 600 | 6381×2200×2636 | 17200 |

On the basis of Z12V190B diesel engine, the 2000 series diesel engine has been greatly improved in terms of improving the reliability, economic performance, and power performance of diesel engine, solving three leaks, appearance quality, and maintenance, etc., so as to better meet the power requirements of various oil drilling rigs, generator sets, and construction machinery. Series 2000 diesel engines can be matched with torque converter sets, coupler sets, and diesel generator sets for driving drilling rigs or mud pumps, as well as fire pumps and flood pumps, etc.

| Engine model | Fuel injection system | Cylinders & Arrangement | Cylinder bore,mm | Piston stroke,mm | Power, kW | RPM,r/min | Total piston displacement,L | Fuel Consumption Rate,g/kW.h | Lub. oil comsumption,g/kW.h | Oil pan capacity,L |

| G12V190ZL | Four-stroke, pressurized intercooler, water-cooled, direct-injection combustor | 12 cylinders V type | 190 | 210 | 990 | 900 | 71.45 | ≤209.4 | ≤1.6 | 200 |

| G12V190ZL-1 | 13 cylinders V type | 814 | 740 | 71.45 | ≤209.4 | ≤1.6 | 200 | |||

| G12V190ZL-2 | 14 cylinders V type | 660 | 600 | 71.45 | ≤209.4 | ≤1.6 | 200 | |||

| G12V190ZL-3 | 15 cylinders V type | 940 | 850 | 71.45 | ≤209.4 | ≤1.6 | 200 | |||

| AG12V190ZL | High - voltage common rail ECU electronic control jet | 16 cylinders V type | 990 | 900 | 71.45 | ≤202 | ≤1.6 | 200 | ||

| AG12V190ZL-3 | 17 cylinders V type | 990 | 900 | 71.45 | ≤202 | ≤1.6 | 200 | |||

| Genset Model | Engine model | Alternator model | Power kW | RPM,r/min | Voltage V | Frequency Hz | Power Factor | Genset Dimension mm | Weight kg | |

| 500GF17-2 | G12V190ZLD1-2 | IFC series | 500 | 1000 | 400/6300/10500 | 50 | 0.8 | 5925×2040×2678 | 5000 | |

| 700GF1-3 | G12V190ZLD1 | 700 | 1500 | 7000 | ||||||

| 800GF4-7 | G12V190ZLD2 | 800 | 1500 | 8000 | ||||||

| 800GFZ-1 | G12V190ZLD3 | 800 | 1500 | 8000 |

Jichai 140 series diesel engine is a high-performance high-speed diesel engine with all intellectual property rights developed by Jichai and AVL. The products are mainly used in light oil drilling rigs, petroleum machinery, and mobile power stations, construction machinery, heavy trucks, and other fields. Can meet all kinds of power generation needs. It has the characteristics of compact shape, simple operation and maintenance, and high power index.

| Genset model | Engine model | Alternator model | Power kW | RPM,r/min | Voltage V | Frequency Hz | Power factor | Dimension mm | Weight kg |

| 400GF30 | JC15 | XN5C series | 400 | 1500 | 400V/6300V/10500V | 50 | 0.8 | 3420×1270×1654 | 3300 |

| 450GF30 | JC15D-3 | 450 | 1800 | 480/13800 | 60 | 3420×1270×1654 | 3300 | ||

| 800GF30 | JC30 | 800 | 1500 | 400V/6300V/10500V | 50 | 4500×1941×2031 | 6500 | ||

| 900GF30 | JC30D-3 | 900 | 1800 | 480/13800 | 60 | 4500×1941×2031 | 6500 |

Jichai series 140 engine is a high-performance, high-speed engine developed by Jichai in cooperation with AVL with all intellectual property rights,It has the feature of high pressure, low energy consumption, high reliability, long - life, meets the TIER2 and European Ⅲ emission standards,it is widely used in oil vehicle drilling rigs, oil specials, wellsite generator sets, mobile power stations or backup power sources, construction machinery, trucks and other fields. Each technical index achieves the international advanced level, the domestic leading level of 5-10 years.

| Model | Cylinders&Arrangement | Cylinders bore, mm | Piston Stroke, mm | Rated power,kW | RPM,r/min | Total piston displacement, L | Heat consumption rate kJ/kW.h | Lub. oil consumption g/kW.h |

| JC15D/T | 6 cylinders, in-line | 140 | 165 | 350 | 1500 | 15.24 | ≤10000 | ≤0.35 |

12V175 diesel generator set is a high-performance power set developed for the working condition of an electric drilling machine. According to the characteristics of oilfield working conditions, the Genset has been designed in terms of starting performance, sudden reduction capacity, and continuous working capacity. In order to realize unattended operation, Genset has installed a remote monitoring system, which realizes the real-time recording of the Genset field data and remote monitoring on the Internet.

| Genset model | Rated power kw | Rotate speed r/min | Frequency Hz | Voltage V | Engine model | Power factor |

| 1250GF | 1200 | 1500 | 50 | 600 | 12V175ZL | 0.7 |

| 1400GF | 1400 | 1800 | 60 | 600 | 12V175ZL | 0.7 |

| Power range | 10~7500kW |

| Gas displacement | 0.1~500×104Nm3/d |

| Maximum exhaust pressure | 52MPaG |

| Application area | It can be used for gas collecting, gas production and gas injection (gas storage), oil and gas treatment and processing, gas lifting, light hydrocarbon recovery, natural gas liquefaction, refining, gas drilling and pipeline pressure testing. |

| Gas inlet pressure | 1.0~2.4MPaG |

| Gas OUTlet pressure | 17~50MPa |

| Gas displacement | 25~100Nm3/min |

| Work Mode | 24 continuous working mode |

| Application area | The compressor set is suitable for drilling operations of pure air, air atomization, air foam liquid, air inflation, and nitrogen in 6 '~ 171/2' wellbore. It is the only air pressurization compressor used for underbalanced drilling in China. |

Series 26/32 natural gas engines are high-power natural gas engines with independent intellectual property rights launched by Jichai to meet the demand of national energy conservation and emission reduction projects, such as long-distance pipeline compressor driving power, offshore drilling platform power, large gas-fired power station, and distributed energy. It has high pressure, high power, high efficiency, low discharge, green, environmental protection, and other characteristics. The engine's gas consumption rate is 8500kJ/kW·h, and its thermal efficiency is higher than 44%. Its power performance, economy and reliability have reached the international advanced level.

| Engine model | Cylinders & Arrangement | Cylinder bore,mm | Piston stroke,mm | Rated power ,kW | RPM,r/min | Total piston displacement,L | Heat consumption ratekJ/kW.h | Lub. oil consumption rate g/kW.h | Start method |

| 16V26/32T | 16cylinders ,V type | 260 | 320 | 4200 | 1000 | 272 | ≤8181 | ≤0.6 | Gas |

| 3780 | 900 | ||||||||

| 12V26/32T | 12 cylinders, V type | 260 | 320 | 3150 | 1000 | 204 | |||

| 2835 | 900 | ||||||||

| Genset Model | Engine model | Alternator model | Power kW | RPM,r/min | Voltage KV | Frequency Hz | Power factor | Dimension mm | Weight kg |

| 4000GF-T | 16V26/32T | The standard configuration is Leleisemar motor | 4000 | 1000 | 6.3/10.5 | 50 | 0.8 | 9435x2930x4175 | 70000 |

| 3600GF-T | 16V26/32T | 3600 | 900 | 13.8 | 60 | ||||

| 3000GF-T | 12V26/32T | 3000 | 1000 | 6.3/10.5 | 50 | 8330x2930x3638 | 48000 | ||

| 2700GF-T | 12V26/32T | 2700 | 900 | 13.8 | 60 |

Functional description:

1)The container is equipped with a distribution box to provide power to all low-voltage loads in the engine room, such as horizontal radiator fans, control screens, lighting, exhaust (supply) fans (for horizontal distribution), chargers, electric heating (optional), oil pumps, electric heating (optional), and outdoor searchlights. It can also be responsible for controlling related equipment (according to project configuration requirements);

2)Two track suspension beams and a hoist are installed on the top of the engine room, with a lifting capacity of 0.5 tons per beam;

3)Inlet of engine air filter and the engine room are equipped with electric heating devices to avoid freezing and blockage (optional);

4)The floor of the machine room is equipped with an axial drive mechanism for the generator, which enables the generator to detach from the coupling by 200mm. (Optional)

5)If the indoor heating temperature in the machine room is not lower than 5 ℃, an insulation layer needs to be installed under the chassis of the machine room, and electric heating heaters (optional) are used inside the machine room;

6)One explosion-proof acoustic and visual alarm lamp is installed outside each machine room. The lighting inside the machine room is an explosion-proof LED lamp with emergency function. Other equipment and boxes do not need to be explosion-proof (optional).

7)Ladder: Install a simple ladder at a suitable position on the box;

8)Configure the fire protection system in the machine room: Install dry powder fire extinguishers as fire extinguishing devices (standard), and other flame detectors, methane leak detectors, smoke detectors, etc. as optional options;

9)Note: The specific configuration shall be subject to the actual situation of the project.

Application case:

Functional description:

1)The container is equipped with a distribution box to provide power to all low-voltage loads in the engine room, such as horizontal radiator fans, control screens, lighting, exhaust (supply) fans (for horizontal distribution), chargers, electric heating (optional), oil pumps, electric heating (optional), and outdoor searchlights. It can also be responsible for controlling related equipment (according to project configuration requirements);

2)Two track suspension beams and a hoist are installed on the top of the engine room, with a lifting capacity of 0.5 tons per beam;

3)Inlet of engine air filter and the engine room are equipped with electric heating devices to avoid freezing and blockage (optional);

4)The floor of the machine room is equipped with an axial drive mechanism for the generator, which enables the generator to detach from the coupling by 200mm. (Optional)

5)If the indoor heating temperature in the machine room is not lower than 5 ℃, an insulation layer needs to be installed under the chassis of the machine room, and electric heating heaters (optional) are used inside the machine room;

6)One explosion-proof acoustic and visual alarm lamp is installed outside each machine room. The lighting inside the machine room is an explosion-proof LED lamp with emergency function. Other equipment and boxes do not need to be explosion-proof (optional).

7)Ladder: Install a simple ladder at a suitable position on the box;

8)Configure the fire protection system in the machine room: Install dry powder fire extinguishers as fire extinguishing devices (standard), and other flame detectors, methane leak detectors, smoke detectors, etc. as optional options;

9)The machine room requires a silent type, with 85dB at 1m.

10)Note: The specific configuration shall be subject to the actual situation of the project.

Application case:

CNPC Chai Gas (coal bed methane) power generation products were first used in the Jincheng area in 2003. Since 2005, the company has increased r&d investment in coal mine gas power generation products, paid attention to communication and cooperation with relevant research institutes of coal mines, and established close ties with China Coal Bed Methane Society, Henan University of Science and Technology, Fushun Coal Branch General Institute and other coal design institutes. Have research and development of coal mine gas proprietary models 8 kinds of high and low concentrations of power to cover 200-1500 kw, adopting advanced gas machine control technology in the world, and the thin combustion theory, in view of the domestic gas drainage discharge process, the characteristics of the volatile gas concentration, through the reasonable matching of the air intake system, makes the gas unit to adapt to the performance of the broader, can burn methane concentration from 8% to 60%, in the range of 3 to 15 kpa pressure of the gas, its performance, fuel economy, safety and reliability have reached the international advanced level. It is distributed in 13 major coal-producing areas, and more than 500 sets of gas (CBM) equipment have been sold in the Shanxi market alone.

| Engine Model | Cylinders & Arrangement | Cylinder bore,mm | Piston Bore,mm | Rated Power,kW | RPM,r/min | Total Piston Displacement,L | Heat consumption rate kJ/kW.h | Lub. oil consumption rated g/kW.h | Staring Mode |

| G12V190ZLW-2 | 12 cylinders V type | 190 | 210 | 550 | 1000 | 71.5 | ≤11000 | ≤0.8 | Electrical starting |

| H16V190ZLW-2 | 16 cylinders V type | 215 | 1200 | 97.53 | ≤9500 | ≤0.6 | Electrical starting/Air Starting | ||

| G12V190ZLWD4-2 | 12 cylinders V type | 210 | 660 | 71.5 | ≤11000 | ≤0.8 | Electrical starting | ||

| H16V190ZLWD-2 | 16 cylinders V type | 215 | 1200 | 97.53 | ≤9500 | ≤0.6 | Electrical starting/Air Starting | ||

| L20V190ZLWd-2 | 20 cylinders V type | 255 | 1600 | 144.6 | ≤9000 | ≤0.6 | Air Starting | ||

| Model | Engine model | Alternor model | Power kW | RPM,r/min | Rated Voltage V | Frequency Hz | Power factor | Dimension mm | Weight kg |

| 500GF-WK | G12V190ZLDW-2 | 1FC Series | 500 | 1000 | 400 | 50 | 0.8 | 5120×2040×2776 | 13800 |

| 1000GF-W | H16V190ZLW-2 | 1FC Series | 1000 | 400 | 6760×2180×2540 | 25000 | |||

| 1000GF9-WK | H16V190ZLW-2 | JFG Series | 1000 | 10500 | 6760×2180×2540 | 25000 | |||

| 500GF-WK2 | G12V190ZLWD2-2 | 1FC Series | 500 | 400 | 5120×2200×2778 | 13800 | |||

| 600GF9-WDK | G12V190ZLWD4-2 | JFG Series | 600 | 10500 | 5120×2200×2778 | 13800 | |||

| 1000GF-WK2 | H16V190ZLWD1-2 | 1FC Series | 1000 | 400 | 6760×2180×2540 | 25000 | |||

| 1000GF9-WK1 | H16V190ZLWD1-2 | JFG Series | 1000 | 10500 | 6760×2180×2540 | 25000 | |||

| 1500GF-WD | L20V190ZLWd-2 | 1500 | 6300 | 9093×3786×2786 | 28000 |

Compressor D seriescan be used for gas collecting, gas production and gas injection (gas storage), oil and gas treatment and processing, gas lifting, light hydrocarbon recovery, natural gas liquefaction, refining, gas drilling, and pipeline pressure testing.

| Power range | 10~7500kW |

| Gas displacement | 0.1~500×104Nm3/d |

| Maximum exhaust pressure | 52MPaG |

| Application area | It can be used for gas collecting, gas production and gas injection (gas storage), oil and gas treatment and processing, gas lifting, light hydrocarbon recovery, natural gas liquefaction, refining, gas drilling and pipeline pressure testing. |

| working medium | Natural gas, coal bed gas, shale gas, oil field associated gas, flash vapor, air, nitrogen, carbon dioxide, hydrogen, nitrogen hydrogen and so on. |